What is the "ClearSealing" technology offered by LEDaquaristik?

As you probably already know, LEDs are sensitive to heat. A high luminous intensity inevitably also leads to a high LED operating temperature, which in turn has a direct effect on the service life of the LED. For this reason, a crucial and indispensable consideration in the design of LED products is how they cope with heat.

Ideally, the LEDs should be mounted "bare" on a good cooling body. The area of use – in aquariums – also makes it essential for the LEDs to have a watertight seal. There are three materials available for achieving all this: Epoxide (synthetic resin), polyurethane (PU) adhesive and silicon.

Most waterproof LED bars available on the market are sealed with epoxide, which means they are very inexpensive. However, from a technical point of view they are not the best choice because they quickly discolour and become brittle.

ClearSealing is a special production process in which a special high-performance silicone gives the LED bars a watertight seal. UV and temperature stable! Although this process results in longer production times and higher manufacturing costs, the characteristics it produces cannot fail to impress:

Temperature:

- Our silicone has a much higher thermal conductivity than epoxide or PU and therefore has almost no effects on the service life. Our LED bars have the big advantage that the LEDs are permanently and directly attached to the cooling body. Thus the heat they create is directly and efficiently conducted away.

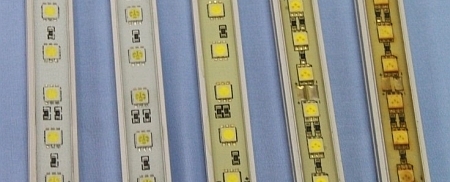

Left: LEDs in epoxide after 3 and 5 months respectively, right: LEDs in silicone after 6 months

External influences:

- The chemical properties of epoxide and PU make the materials highly sensitive to external influences such as heat and moisture. Therefore they can quickly become very hard, stiff and brittle, which adversely affects their role as sealants. Our silicone is much more stable and retains its properties.

Transparency:

- Our silicone is highly transparent, whereas epoxide and PU increasingly reduce the luminous intensity.

Beam angle:

- The production process is specially designed for the materials used and their properties. Thus we are able to achieve a beam angle of almost 160° with ClearSealing technology. And we do that completely without reflectors or lenses!

UV stability:

- Our silicone is much more UV stable. Epoxide and PU go yellow by comparison after just a few months even with a low proportion of UV light.

Left: LEDs in silicone after 1 + 3 months, right LEDs in epoxide after 1,2,3 months respectively.